IMAGIC

Integrated Magnetic imAgery

based on spIntronics Components

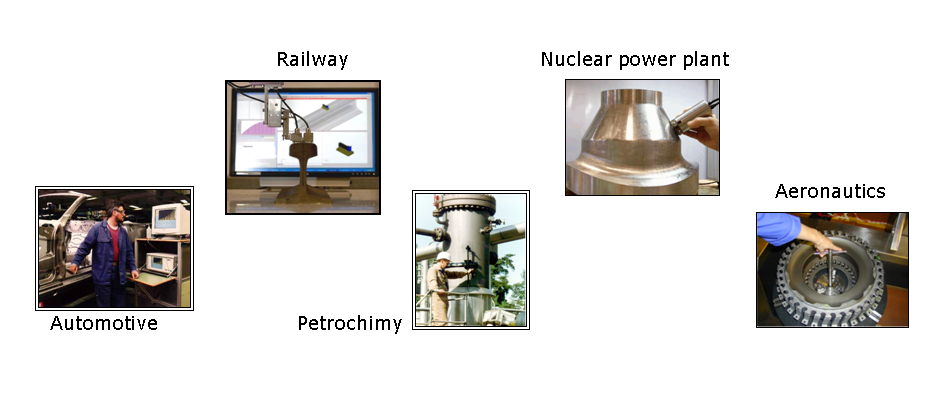

Structures reliability, installations safety and products quality are requirements that industrial sectors must take into account. The stake is to be able to guarantee the integrity of the structures, and that requires the ability to detect a defective component during its manufacture or in service inspection. Industries have today a strong pressure to reinforce the reliability and the safety of their products, while improving their profitability and productivity. To take up this challenge, they are strongly users of non destructive testing (NDT) which gathers methods aiming at providing information on the health of a part or structure without impairing its future usefulness. NDT addresses nowadays a lot of industrial sectors such as transport (railway, automobile, and aeronautics), nuclear or petrochemical field (Fig.1).

Figure 1: Typical applications addressed by Non Destructive Testing.

NDT is even more necessary in applications requiring severe operating environments or involving public safety. In transport (aeronautics, railway, automobile) and nuclear fields, the undetected generation, propagation and failure of a defect leading to the rupture of the structure would be a catastrophic situation.

Among the existing NDT methods, Eddy current (EC) inspection is widespread, ensuring subjacent or surface breaking flaws detection. This method knows today a deep change to fulfil performances for detection of very small and deep flaws, while decreasing inspection time. Classical winding coils are the most commonly used EC sensors, but their spatial resolution and sensitivity are limited because of the technology itself.

In this context, spin electronics based magneto-resistive (GMR, TMR) sensors are promising because of their frequency independent sensitivity, their small size, and their collective manufacturing process which facilitates the fabrication of array probes. To improve the performances of the EC method, IMAGIC aims at developing a new integrated magnetic imagery based on highly sensitive GMR and TMR array sensors that allow a very good spatial resolution. The objective is to lead developments to the industrialization of smart systems combining technological developments (array sensors, integrated electronics) with sophisticated treatment tools (sensor design, flaw characterization).

In the beginning of the project the application cases of planned imagery system have been defined by the industrial partners. The EC probe designs have been proposed based on simulations. The materials for GMR and TMR sensors have been chosen. Electronics solutions for the EC probes are under development.